For the processing of hot-melt adhesives in industrial applications and crafts, a wide variety of applicators and dosing systems are available.

The selection of the suitable applicator depends on specific parameters such as

The selection of the suitable applicator depends on specific parameters such as

- Scope of the application (size of the glued areas, number of parts to be glued)

- Type and properties as well as shape of the hot-melt adhesive used

- Application type and purpose (e.g. dots or lines, film application, spraying or coating, fixating, filling or sealing)

- Conditions in the production plant (such as compressed air connection, facilities)

Fully automated production lines and roller application devices are used as well as tank systems with manually guided application heads or completely hand-guided hot-melt glue guns. In addition, it is possible to integrate glue guns into robot systems, for stationary and semi-automated use.

The field of hand-held hot-melt glue applicators is divided into the following areas

- the transport technology of the adhesive (manual or pneumatic)

- the type of material to be processed (reactive or non-reactive)

- the shape of the hot-melt to be processed (granules / pellets, pillows, sticks, 43 mm candles, aluminum cartridges)

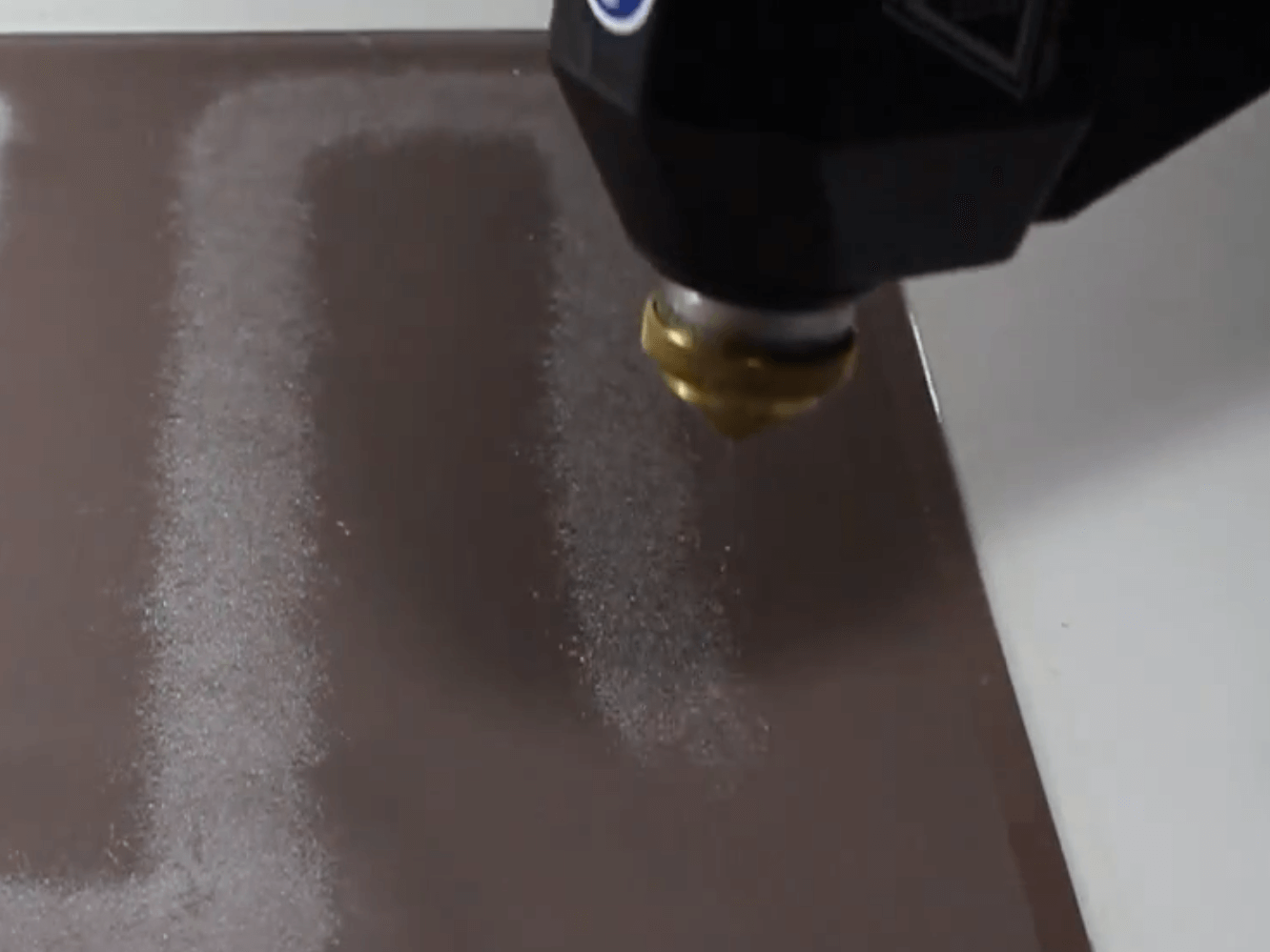

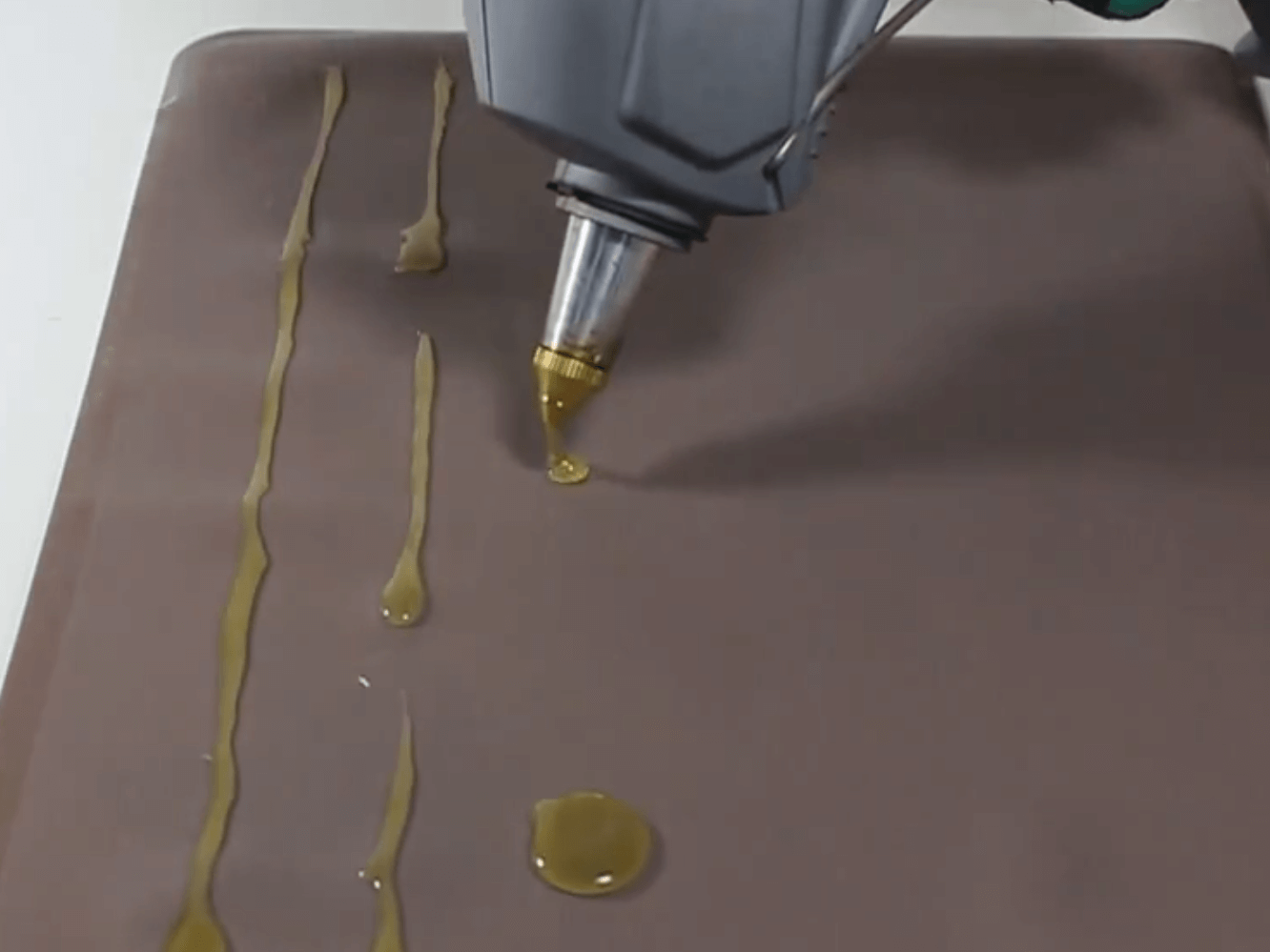

- the desired application form (dot or line application, spray application)

- the operational equipment (e.g. compressed air supply)

You need advice?

Do you have a gluing problem?

The reka glue guns

Choose your glue gun according to the type of application

Choose your glue gun according to the glue type

No compressed air available? MS 200.E

Working comfortably with compressed air? TR 50.5, TR 55 LCD, TR 60 LCD spraying system

No compressed air available? MS 200.E

Working comfortably with compressed air? TR 50.5, TR 55 LCD, TR 60 LCD spraying system

For dot and bead application: TR 70 LCD, TR 700 (inexpensive with fixed temperature setting)

Ideal for large-area spray application: TR 80 LCD (the all-rounder)

The all-rounder that covers all applications is the TR 80 LCD spray system. The TR 80 LCD processes both reactive hot melt adhesives in disposable aluminium cartridges and non-reactive hot melt adhesives, for example in a reusable cartridge. With the TR 80 LCD the application pattern can be changed from spraying to bead application quickly and conveniently.